Services

What we do

.png)

At Ashi Industries, we offer a comprehensive range of manufacturing and fabrication services to meet the diverse needs of our customers. Our state-of-the-art facilities and experienced team enable us to deliver high-quality solutions across various domains.

VMC(Vertical Machining Center)

Our Vertical Machining Centers (VMC) are engineered to deliver exceptional precision in tooling and prototyping applications, combining high-speed CNC technology, rigid machine structures, and advanced cutting capabilities. We specialize in creating custom jigs, molds, dies, and functional prototypes with complex geometries and superior surface finishes, working across a wide range of materials including metals, alloys, and engineering plastics. This enables us to support rapid design iterations, reduce lead times, and ensure every component meets exact client specifications with unmatched accuracy and consistency.

Stamping

We provide stamping services using high-tonnage presses to shape and form metal components with precision. Our stamping process ensures consistent quality and efficiency, making it ideal for automotive and industrial applications.

Receiving Gauges

Quality control is paramount at Ashi Industries. Our receiving gauges are used to inspect and verify the dimensions and tolerances of incoming materials and components, ensuring they meet stringent quality standards before production.

Fabrication

Our fabrication services cover a wide range of metalworking processes, including cutting, bending, and assembling metal structures. We manufacture industrial pallets, trolleys, and custom fabrications tailored to your specific requirements.

Welding

We offer professional welding services for various applications, including MIG, TIG, and spot welding. Our skilled welders ensure strong, reliable joints and structures, adhering to industry standards and specifications.

Wire Cut

Our wire cut EDM (Electrical Discharge Machining) services provide high-precision cutting for intricate and complex shapes. This process is essential for creating detailed tooling and components with tight tolerances.

Prototype Samples

We specialize in creating prototype samples to help you visualize and test your designs before full-scale production. Our rapid prototyping services enable quick turnaround times, allowing you to refine and perfect your products.

Tooling

We design and manufacture high-precision tooling, jigs, and fixtures in-house. Our tooling solutions are engineered to enhance production efficiency and ensure consistent quality in your manufacturing processes.

Pipe Bending

Our 3-axis CNC pipe bending machine delivers precision and consistency for complex bending requirements, enabling smooth, accurate curves with minimal material deformation. Capable of handling a variety of pipe diameters and materials including stainless steel, mild steel, and aluminum, it is ideal for creating custom bends for tooling, prototypes, and specialized production parts. With advanced CNC controls, we can achieve high repeatability, maintain tight tolerances, and execute intricate bend geometries, ensuring every component meets exact specifications while reducing waste and production time.

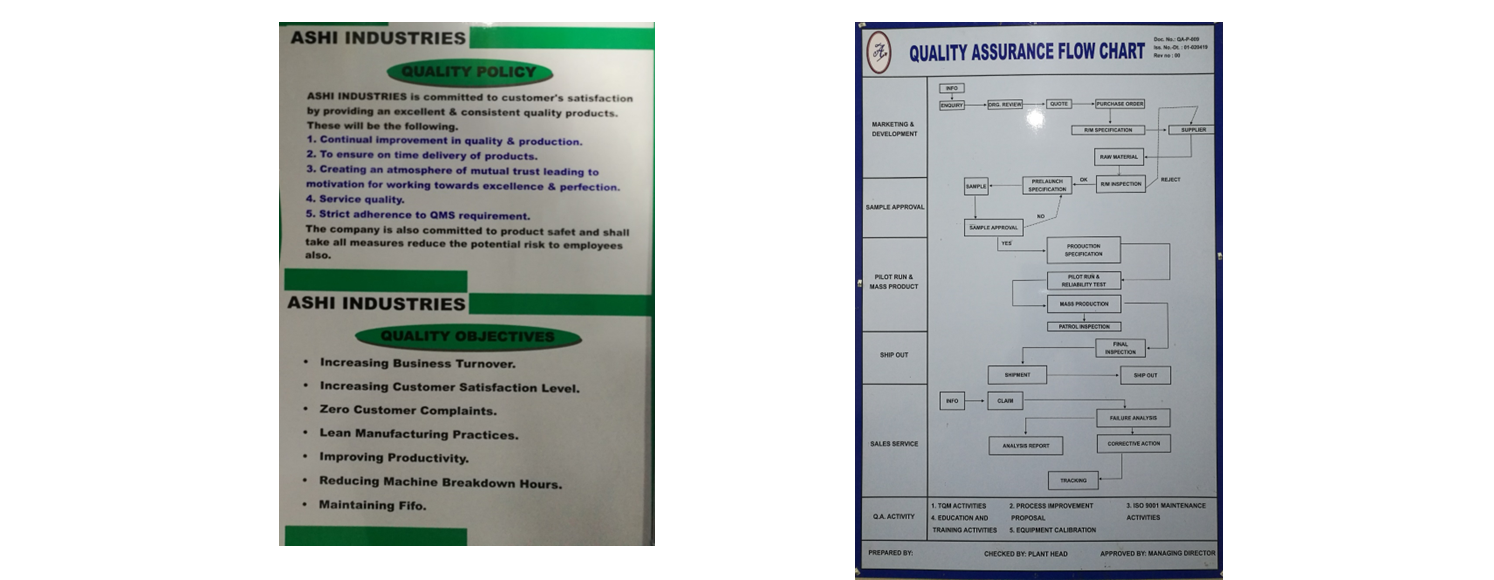

Quality Policy and Objective

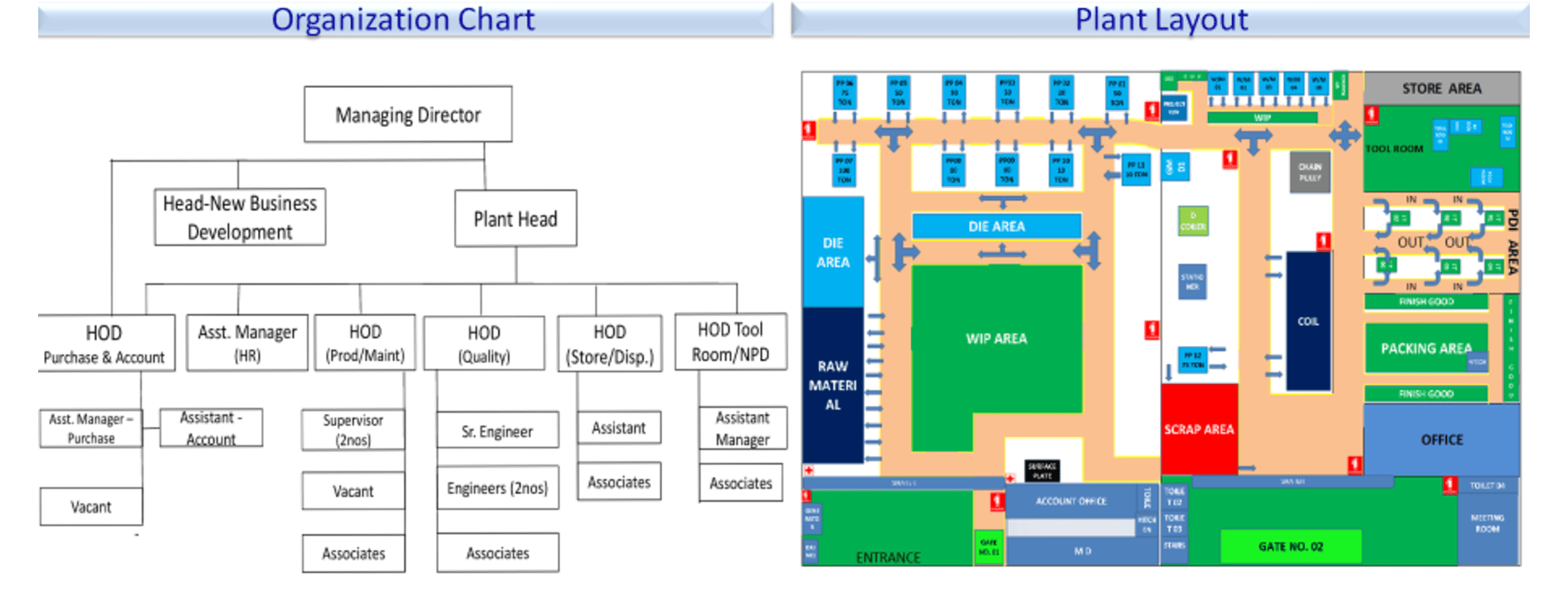

Organization Chart & Plant Layout

Plant Facility

.png)

Quality Instrument

.png)